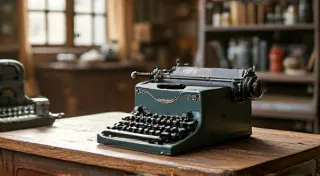

Restoring a Hammond Typewriter: Common Challenges and Solutions

Hammond typewriters hold a unique place in vintage typewriter history. Known for their sturdy construction and innovative features, they’re a rewarding machine to restore. However, their complexities also mean that Hammond restoration presents specific challenges. This guide addresses some of the most common issues encountered when bringing a Hammond typewriter back to life.

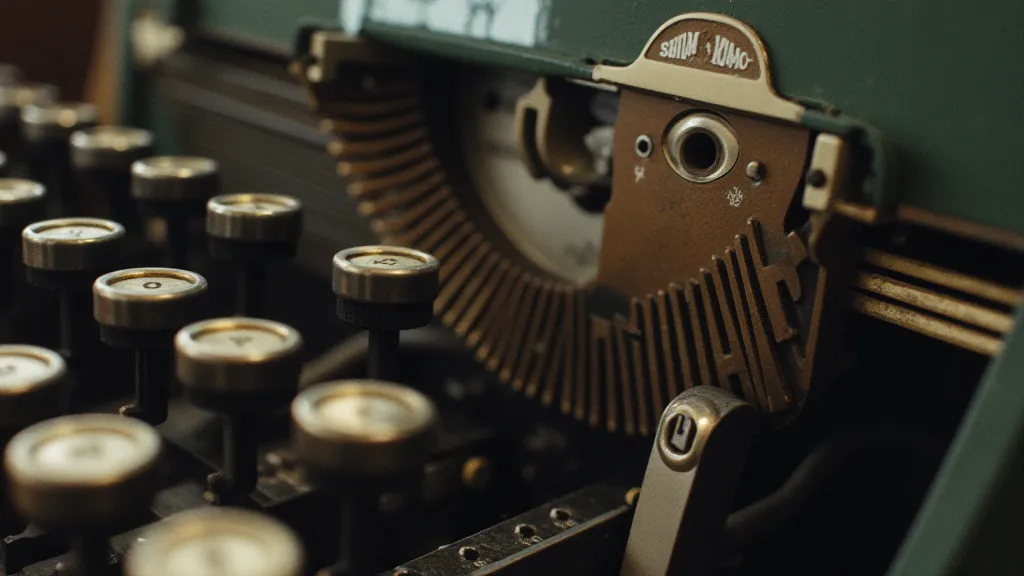

Understanding the Hammond: A Brief Overview

Before diving into restoration, it's helpful to appreciate the Hammond's design. Hammond typewriters were often equipped with unique mechanisms such as the "Perfect Action" – intended to provide a smoother typing experience. Recognizing these features is crucial for proper diagnosis and repair. Hammond’s complexity underscores the vital role of consistent maintenance and proper lubrication. Understanding how a typewriter works, and the specific needs of different models, can be greatly assisted by resources available online, such as guides dedicated to the importance of lubrication in typewriter restoration.

Common Restoration Challenges & Solutions

1. Carriage Issues: Sticking, Binding, and Misalignment

One of the most frequent problems with Hammond typewriters is carriage malfunction. This can manifest as a carriage that sticks, binds, or is misaligned. Here’s a breakdown of potential causes and solutions:

- Cause: Dried Lubricant. Years of neglect often result in hardened grease and oil seizing up the carriage mechanism.

- Solution: Thorough Cleaning and Lubrication. Carefully disassemble the carriage rails and related components. Use a solvent like mineral spirits to remove the old lubricant. Then, apply a typewriter-specific oil sparingly. Avoid excessive oil, as this can attract dust and create another problem.

- Cause: Bent or Damaged Carriage Rails. The rails guide the carriage’s movement. Even slight bends can cause binding.

- Solution: Rail Straightening. If the bends are minor, carefully try to straighten them using gentle pressure. More severe bends may require rail replacement – a more advanced repair.

- Cause: Worn or Damaged Carriage Lock. The carriage lock keeps the carriage in place when not in use. A faulty lock can prevent smooth movement.

- Solution: Lock Adjustment or Replacement. Try adjusting the lock mechanism. If that doesn't work, replacement is usually necessary.

2. Type Bar Problems: Noise, Sticking, and Alignment

The type bars, responsible for striking the paper, can also present challenges. Sometimes, the problems with type bars are just one component of a larger issue affecting the whole machine. Before undertaking repairs, ensuring the underlying problem isn’t a more systemic issue is best practice. Understanding the nuances of different typewriter models, particularly when facing complex repairs, can be aided by resources such as guides dedicated to understanding and fixing common Underwood typewriter issues.

- Cause: Dirty or Worn Type Bars. Dust and debris can accumulate on the type bars, causing them to stick or strike unevenly.

- Solution: Cleaning and Alignment. Carefully clean each type bar with a soft brush and solvent. Check their alignment and adjust as needed.

- Cause: Damaged Type Bar Springs. The springs that power the type bars can weaken or break over time.

- Solution: Spring Replacement. Type bar springs are relatively inexpensive and readily available. Replace any damaged springs.

3. Ribbon Issues: Frays, Breaks, and Uneven Distribution

Ribbon problems are common in all vintage typewriters, but Hammond ribbon mechanisms can sometimes be a little more intricate. Replacing ribbons is a relatively straightforward repair, but deeper ribbon system problems are typical of many vintage machines.

- Cause: Dried-Out Ribbon. The ribbon degrades over time, becoming brittle and prone to breakage.

- Solution: Ribbon Replacement. The best solution is to replace the ribbon with a new one. Consider using a high-quality ribbon designed for vintage typewriters.

- Cause: Ribbon Feed Problems. The ribbon feed mechanism may be gummed up or damaged.

- Solution: Cleaning and Adjustment. Carefully clean the ribbon feed rollers and escapement mechanism. Adjust the tension as necessary.

4. Escapement Problems: Erratic Typing & Misalignment

The escapement controls the spacing between characters. Problems here can result in erratic typing. The escapement is a complex and critical component, and diagnosing issues can be challenging. Understanding how escapements function across different typewriter models can significantly aid in identifying the root cause of problems.

- Cause: Dried Lubricant or Debris. This interferes with the escapement’s movement.

- Solution: Cleaning and Lubrication. Careful cleaning and lubrication are essential.

- Cause: Worn or Damaged Escapement Pawls. These small parts engage with the platen to advance the paper.

- Solution: Pawl Replacement. Replacing worn escapement pawls is a common repair.

5. Key Stickiness & Uneven Action

Keys may stick or have uneven action due to dried lubricant or damage to the key levers. Consistent, proper maintenance is the best way to avoid key stickiness. However, when issues arise, a systematic approach to diagnosis and repair is necessary.

- Cause: Dried Lubricant. The most common culprit.

- Solution: Cleaning & Lubrication. Thorough cleaning and lubrication of all key components.

- Cause: Bent Key Levers. Carefully straighten any bent levers.

Final Thoughts & Resources

Restoring a Hammond typewriter requires patience, attention to detail, and a willingness to learn. It's a rewarding endeavor, but challenges are inevitable. Beyond the specifics of Hammond typewriters, understanding the broader context of vintage typewriter restoration – including identifying various models – is beneficial. Resources such as a visual guide to identifying typewriter models can be particularly helpful. While this guide provides a foundation for common repair tasks, don't hesitate to consult diagrams and repair manuals specific to the Hammond model you’re working on. And, as with any complex mechanical task, seeking advice from experienced typewriter repair enthusiasts is invaluable. Finally, understanding the characteristics and repair considerations for other popular models, such as the Remington Rand Model 9, can offer valuable insights applicable to Hammond restoration as well.